Target Value Delivery (TVD)

Introduction to Target Value Delivery

When using traditional delivery models, waste is frequent as teams fail to properly plan ahead and communicate goals with one another. The removal of waste is one of the six tenets of the Lean Construction Institute, and Target Value Delivery (TVD) is a crucial Lean tool to help teams achieve that.

A prime example of how traditional delivery models lead to waste occurs early on in the design phase; you generally don’t receive budgetary approval from the owner on a construction project until the A&E team has already finished with designs. This necessitates rework, which causes projects to be delivered late and over-budget – which happens to 70% of projects.

Target Value Delivery is a very different type of project delivery method from the traditional, large-batch process of design, estimate cost and value engineering — a process replete with waste. Clients do not value the process of rework and loss of quality that comes from this traditional “value engineering” process. The driving force of Target Value Delivery is to increase value while decreasing production cost for all team members.

Target Value Delivery also aims to improve workflow by encouraging the various teams on a project to communicate throughout the project’s development, setting clear goals for one another before a project is approved thereby maximizing value to the stakeholder.

What is Target Value Delivery?

A disciplined management practice to be used throughout the project to assure that the facility meets the operational needs and values of the users, is delivered within the allowable budget, and promotes innovation throughout the process to increase value and eliminate waste (time, money, human effort.)

Explore LCI's GlossaryBusiness Case

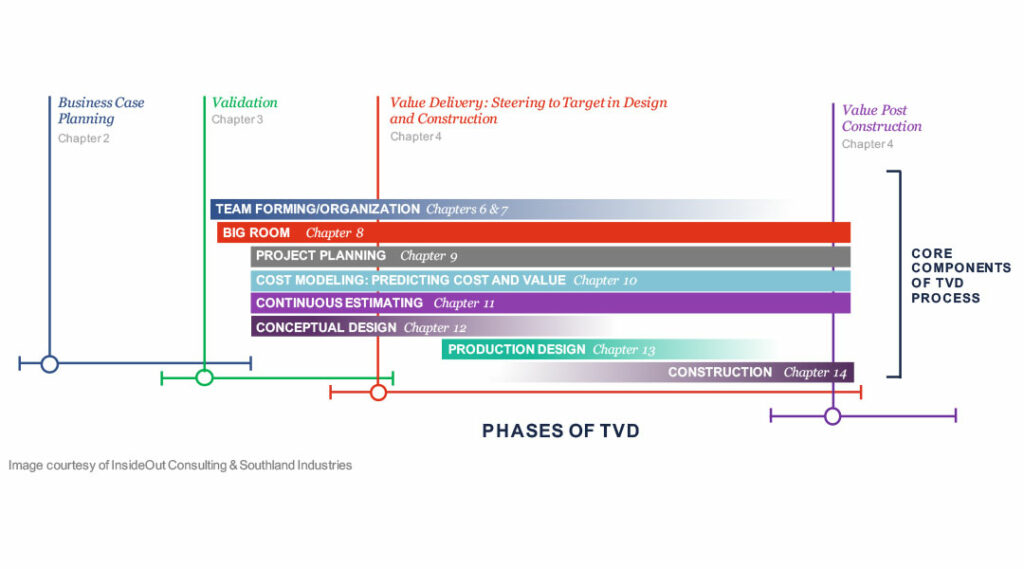

During this phase, the owner of the project provides the operational use/benefit proposition that initiates the development of the project. This is the purpose or “why” that becomes the anchor of the project. During this time the project Value Definition Statements are also developed.

During this stage, Expected Cost is defined by the team. Expected Cost is the amount the owner is willing to spend for the total project. Spending time in this phase is critical to setting the path for success for the project.

Validation

In this phase, the project team (owners, designers, construction team) determine whether the project is viable based on the Business Case and define what project success would mean by developing clear Conditions of Satisfaction (CoS) with measurable outcomes. The Conditions of Satisfaction serve as an anchor that the project team refers to throughout the design and construction process.

During this phase, Scope Definition and a Cost Model are created to meet the Expected Cost. This also serves as a guide for the team during the project. Once these are developed, the team can start to work on the actual design of the project.

Moving forward the Expected Cost or Current Working Estimate is used continuously as the best estimate of what the project will cost at any given time.

As part of the final output of the Validation Phase, the team aligns on a Target Cost. This is the team goal for the total project which should be either equal to or less than the Allowable Cost and Expected Cost. Ideally it should be set at less than best-in-class past performance to create a sense of necessity to drive innovation and waste reduction into the design and construction process.

While many phases overlap, the decision to advance from the Validation phase to the next one must be intentional and clearly recognized by the project partners. All teams involved in the project must fully agree to its parameters including Scope Definition, Value Definition, Conditions of Satisfaction, Current Expected Cost, and Target Cost before advancing to the next stage.

Value Delivery

This is the stage where the work begins. During this phase, work is processed in small batches toward intermediate milestones/decision points. Breaking up the work into small batches is effective at eliminating waste while providing an opportunity for continuous process improvement to take place.

Project teams should implement Big Room approaches to ensure that the work of the project is advanced collaboratively.

Value Post-Construction

At this stage, the Business Case and target values established during Validation are reviewed for actual outcomes. The predetermined measurables are also analyzed to see if the project met the Conditions of Satisfaction.

The purpose of this phase is to ensure that teams continue to improve their Lean skill sets. Continuous improvement is a key tenet of Lean thinking and using a Lean delivery model means identifying ways to remove waste in future processes.

Target Value Delivery Continuous Estimating

When using traditional delivery models, the design team estimates cost against the budget only at previously established checkmarks. This leads to a lot of redesigning and cutting of crucial elements and value as the team realizes their design is going to be over-budget.

Enter Target Value Delivery Continuous Estimating, which drives the team to continuously check itself against the Cost Model, Scope Definition, and Conditions of Satisfaction as the design progresses. This process greatly reduces rework and ensures that the project can remain on-budget while adhering to all Conditions of Satisfaction.

What is Big Room?

Big Room refers to a project approach of bringing key individuals together to speed communication and decision-making, and to reduce siloed thinking or approaches. Big Room is a recurring event that maintains the flow of communication throughout the project’s delivery.

It brings key stakeholders together to collaborate, plan, update, solicit resources, invite feedback, demonstrate accountability, make decisions, schedule events and compare the project’s current state to the published goals or Conditions of Satisfaction.

Learning Target Value Delivery

The Lean Construction Institute is committed to transforming the design and construction industry by providing Lean educational resources, conducting research, and facilitating local and national Lean events. It is only through the power of the LCI Corporate Members that LCI is able to offer the supplementary resources below.

Lean Assessments

How strong is your Lean knowledge? Take a Lean assessment to determine your current state so you have a baseline for improvement. Lean assessments are available for individuals, teams, and organizations alike. Whether you’re new to Lean or are an experienced Lean practitioner, Lean assessments are a great way to get started at LCI!

TAKE ASSESSMENTMore Lean Topics

From 5s to IPD, explore popular Lean design and construction topics below.